So very true.

I made a claim last year that I was going to make a 100-mile skirt. I am going to use the pattern from the Claudia Evilla skirt by Ruth Sorensen. I featured the finished version of my first skirt back in August 2011. It's a great skirt and I love everything about it.

Since then I've been making the yarn. Or thinking about making the yarn, mostly thinking about it to be honest.

I had a lot of work to do to even get to the spinning stage -- first I had to comb all that nasty alpaca; then I had to get more of it which required asking a friend to return I gift I had given her. Then in another panicked moment of "I don't have enough fibre to make this skirt" I had to ask another friend to give me her March 2011 fibre club braid.

Then there was the spinning. Here's what I've spun up this far. It may not look like a lot (she writes defensively) but it's spun really fine and it's a lot of yardage.

I want to start plying these singles, but I want to be absolutely sure that I have more blue yarn than the grey -- so I"ll make one bobbin of a two-ply blue and grey using every inch of the grey. Any left over blue will be added to and used to ply with the second grey bobbin. My plan is to make a 2 x 2 cabled yarn, using blue and grey singles. I blogged about it in late January, here's the result of my experiments.

So while I watched the repeat of the Canada/US junior hockey game this morning, I got spinning some more of the blue. I said a while back this was going to be a spinning marathon, I just have to get down to it, because as I noted in the title of this blog post, this skirt ain't gonna make itself.

And if, but probably when I run out of yarn, I still have all of this fibre waiting to be processed and spun. This is the only project I am going to do for the next two days. Let's see how far along I get.

My goal is to use locally sourced wool, mohair, llama & alpaca in my spinning workshops and fibre creations. See the results I obtain with the help of fibre producers in my region and my own stubborn temperament. It all happens here in Glen Valley, BC

Sunday, December 30, 2012

Wednesday, December 26, 2012

Knitting on the Go: Part 1

I live in the countryside outside of Vancouver. I work in the city. While often I am able to work from home, I do spend a considerable amount of time commuting each week. As a result, I've learned how to knit on the go.

Knitting on a bus, train or even in a car can be a tricky business. You don't have a lot of space, in fact there is very little elbow room. It's often difficult to consult patterns, especially ones in books. With the exception of mitts or hats, it is hard to try things on for size. I leave early and arrive home late so many times it's dark on the bus. Because of the myriad of distractions around you, the knitting you are doing needs to be fairly mindless, but not too much so or it will lull you in sleep. And finally, some people are self-conscious about knitting in public. People tend to stare at you and some even ask questions. With all these challenges in mind, why on earth would you even try?

I conquered the process of knitting on the go due to the basic facts that on my commute I have an abundance of time, my hands are free, and I desperately need something to distract me from the tedium of the travel around me.

So here are a few things I've learned. First, the item I'm knitting has to be compact. A pair of socks, mitts or a hat are great things to knit on the train. Having a pattern that is easily to memorize is an added bonus. That's where these lovely mitts come in. They are from the yarn I dyed on a Good day to day. The yarn for these mitts came from the Magic of rainwater experiment.

I love the Baby Fan Lace mitts by Morgan Wolf. They are lovely to knit and the fan lace pattern is easy to memorize. The only problem with knitting these is when I come to the thumb gusset. It's not a difficult thing to do, but it does require concentration. The thumb gusset increases happen on every third row and the fan lace pattern is over four rows. So to stay on track you need to follow the lace chart and check off your progress. This is a wee bit tricky on the bus/train as you need to keep the pattern nearby and a pen at ready.

So here's my solution to that problem.

I decided to try something different around the treatment of the thumb. When I got to the place where I'd start the gusset I did so by defining the stitches for the gusset with yarn overs. Then I stopped the lace pattern and knit in straight stocking stitch. I marked each increase row with a yarn over on each side of the increase. Because I was putting in these yarn overs I had to decrease on each side of them as I did not want the gusset increases to come from yarn overs, but from "make one left" and "make one right". [I'll write the whole pattern out soon.]

The point I am trying to make is that by using yarn overs as a "marker" I could do a couple of things. I was able to add a decorative element to the pattern which also served as an easy way to read my progress. It's easy to count what row you are on after a yarn over, something that you could do by feel and in dim lighting. After I set aside the thumb stitches, I continued in the regular pattern right to the end.

So that's a way I did minor adjustments to a pattern which enabled me to knit it with ease on the bus.

I love these mitts. Everything about them. They are truly 100-mile wear.

Sunday, December 23, 2012

Acacia Farm Half Mitts - complete

It was with great joy that I handed over to Jacqueline and Linda the six pairs of mitts I made from their fibre. Here they all are. All are hand spun, hand knit, and four of them are hand dyed. Their reaction to these mitts made all of it worthwhile.

I haven't really decided which one was my favourite, but these two below are in the running. The pattern for this one is Baby Fan Lace that I've used many, many times before. I love this pattern. It's easy to do, easy to manipulate. I made this pair from a fingering weight I spun up of blended fibres. They were a light grey but I threw them into the dye pot at the last minute. And I am glad I did.

This is another pair that is in my favourite list. It's just my standard mitten pattern instead of a ribbed cuff I made a 3 x 1 rib throughout. I love the way this yarn (made from the blending the dark grey and white fibre and then plying the blended fibre with a singles made of pure dark grey or white) behaves when over dyed with blue. It looks like denim.

The other day I noticed that my own pair of half-mitts is a little worse for wear. Now that all the Christmas preparations are done, I can get into my studio and get started on a pair (or two) of these for myself.

Sunday, December 9, 2012

Mitts #4 and #5 for Jacqueline

I am in the process of finishing up my knitting agreement with Jacqueline. In exchange for 10 lbs of washed fibre (5lbs of dark grey, 5lbs of white) I agreed to make her six pairs of half-mitts. Two for men, four for women.

I've got five pairs made, here's #4 and #5 where I got out the dyes and had some fun with colour. The orange skein used to be all white. The blue/green skein was 75% white and 25% grey. I love the way the grey tones down the colour, while the white shows the true hue. Combined in one yarn it adds depth.

Here's pair #4 complete except for weaving in the ends, and the beginning of pair #5. This is my second attempt at pair #5. I had 3/4 of a mitt knit up in a lace pattern and finally admitted it was too large. So it ripped it out and started all over again. Put me a bit behind schedule, but the second attempt is much nicer.

I finished the orange pair last night. And here they both are: #4 and #5 complete with the ends woven in. I apologize about the quality of the photos, I can't find my camera in my disaster of a studio, so I've been relying on the camera in my bberry.

Happy spinning.

Wednesday, November 28, 2012

Variations on a theme

I mentioned in an earlier post that I obtained some wool from Acacia Acres farms. A dark grey romney named Ashley and a white romney named Ebony.

The plied yarn from these singles, are the skein on the left. The skein on the right is a two-ply of blended greys and white Ebony.

I am really happy with this yarn -- both skeins are going to be knit up into half-mitts. Haven't decided if I will do any dyeing with these yet. But that's a whole other variation on the theme.

Monday, November 26, 2012

An exploration of yarn structure

Two weekends ago I taught a 6-hour spinning workshop called From Mundane to Amazing: An exploration of yarn structure. It was hosted by the Langley Weavers and Spinners Guild. There were eight participants and all were game to have fun and really open to learning new things. It was a great day.

Here was the plan for the day.

Here was the plan for the day.

From

Mundane to Amazing: an

exploration of yarn structure

1. Spinning warm-up: playing with twist. We started with a bit of a warm-up, just to get folks spinning in a relaxed way. While we were doing this, we talked about the decisions we made when we sat down to spin. For the most part, people didn't make a lot of decisions, they just sat down and spun the same way they have always spun. That's why many of us feel like we are making the same yarn over and over and over again.

After the warm up we got down to spinning a bunch of samples using a variety of techniques with varying amounts of twist in the singles yarn and in the plying process.

After the warm up we got down to spinning a bunch of samples using a variety of techniques with varying amounts of twist in the singles yarn and in the plying process.

2. Making 2-ply yarn

·

High twist

singles > high twist ply

·

High twist

singles > low twist ply

·

Low twist

singles > high twist ply

·

Low twist

singles > low twist ply

3. Making 3-ply yarn

·

3 ply chain –

Navajo plying

4. Making singles yarn

·

Deconstructing

commercially spun singles yarn

·

Spinning and

un-spinning for soft singles

5. Replying yarn – cabled and crepe structures

·

2-ply X 2-ply

cables -- called a 4-ply cabled yarn

·

3-ply (chained)

X 2-ply cables

·

2-ply X singles

(crepe)

6. Bonus yarn

·

Working with fibre in the bag, make some yarn using any technique learned today.

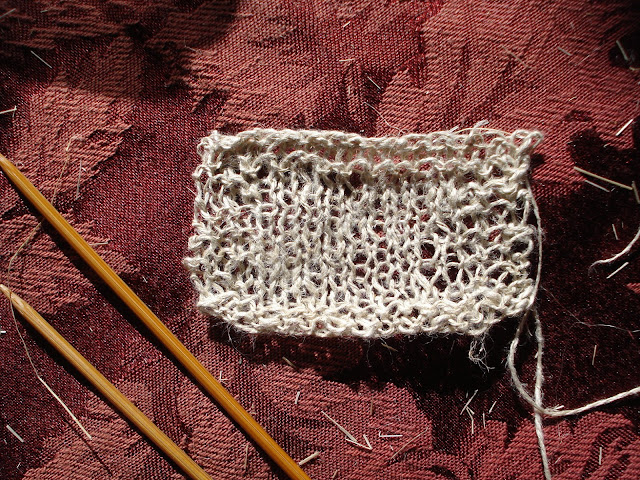

It was a great day and we didn't get all the samples done. But at the next guild meeting I gave out bags that contained the fibre for the last "mystery yarn" exercise. Here's a photo of one of the participants samples from a good part of the day. Lovely spinning.

Thanks everyone for being such good sports. It was a marathon of spinning and everyone played along.

It was a great day and we didn't get all the samples done. But at the next guild meeting I gave out bags that contained the fibre for the last "mystery yarn" exercise. Here's a photo of one of the participants samples from a good part of the day. Lovely spinning.

Thanks everyone for being such good sports. It was a marathon of spinning and everyone played along.

Thursday, November 1, 2012

Flax to Linen Slide Show for the LWSG

On Tuesday, November 20th, I am doing the educational program for the Langley Weavers and Spinners Guild. I am doing a slide show of the process of growing, drying, rippling, scutching, combing and spinning flax to linen. It was easiest to have all the photos together here on my blog and then click on them one after another.

Friday, October 12, 2012

Flax to Linen Photo Shoot -- nearly the finale

Here it is. Finally. A 5m mini-skein of linen from my very own flax field. This is not what the whole field will produce! There's much more to come, but I was anxious to see what it was like, so I finished up a couple of stricks and spun the fibre. In so doing I learned a few things.

1. Flax needs to ret until you can see the linen being released from the straw. In the murky retting water it looks like angel hair. Keep moving the water around to help with the release of the linen.

2. Flax has to be very dry for the next stages. So full-on sunshine for several days and a cover at night to protect from the dew is essential. The sunshine also helps to bleach the linen a bit.

3. Pounding the flax with a rubber mallet against a flat rock further helps to release the linen from the straw. It's a good workout for your upper arms. This stage is called Breaking.

4. The more you bash it against the rock, the more you will see the linen. When most of the straw is flat, that's when you can start the next stage: Scutching. That's where you break the straw into smallish bits so it will fall away from the linen. There are tools that help to do this, but I just broke it with my hands.

5. Wool combs are not the best tools to help remove the straw from the linen which is the next stage: Hackling. I got the best result from my cotton hand cards -- not used in a hand-carding technique. I laid the carder flat and ran the straw-laced linen strick through it a few times, hanging on good and tight. Here's what I got from bashing and combing a couple of stricks of flax.

6. The most important thing I learned is that despite my new found skills at growing, harvesting and producing linen for spinning, I DON'T REALLY KNOW HOW TO SPIN THE DARNED STUFF.

Yet.

It never occurred to me to research how to spin linen. I had a vague recollection from past reading that linen is wet-spun to keep the fibres aligned -- I did that. It was only after I made a mini-skein from an over-twisted double-ply spinning technique and produced the most uninspiring hard yarn I have ever worked with did I think to check some expert sources (the internet) to see what I had done wrong.

Thank heavens the disaster was in my spinning technique because I was ready to put the rest of the unprocessed flax onto the compost heap!

All is not lost, I just have a whole new skill to master. Spinning flax. And you thought this adventure was nearly over. It's only just begun.

Subscribe to:

Posts (Atom)

.jpg)